| Test items | Unit | DuraFloor | Epoxy | Inorganic floor materials |

|---|---|---|---|---|

| Eco-friendliness (HCHO) |

㎎/㎡h | 0.001 | - | - |

| Incombustibility | Rating | 100% incombustibility | - | Fire resistance rating |

| Compression strength | ㎏f/㎠ | 600 | 400 | 500 |

| Wear resistance | g | 0.02 | 0.2 | 0.08 |

| Adhesion Strength | Psi | 1000 | 134 | 134 |

| Friction coefficient | %(Epoxy standard ) | 200 | 100 | 80 |

| Contamination level | Duration | Semi-permanent | 2years | 2years |

| Product lifespan | - | Very few | High | High |

| Frequency of scratches | - | Very few | High | High |

| Workability | Per 1000㎡ | 5days | 4days | 4days |

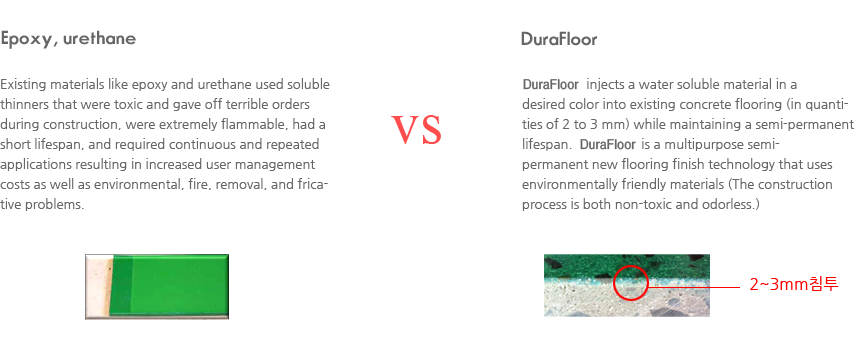

| Item | DuraFloor | Poly urethane | Epoxy lining | Ordinary epoxy |

|---|---|---|---|---|

| Key components | Water-soluble dyes, additives, reinforcing agents |

Urethane polymer Compounds | Solvent-free epoxy resin | Epoxy resin polymer compounds |

| Color | Looks similar to a water-color painting (translucent color) | Looks similar to an oil painting (clear distinctions among colors) | Looks similar to an oil painting (clear distinctions among colors) | Looks similar to an oil painting (masking) |

| Product features | 1. Satisfies eco-friendliness

requirements halfway through

and at the end of construction 2. Satisfies incombustibility requirements in the event of a fire (produces no toxic gases ) 3. Complies with anti-skidding requirement through hydroplaning. 4. Reduces tire screeching sounds 5. Cost-effective in maintenance due to a semi-permanent, long -term use 6. Resistant to contamination 7. Leaves no defects at a later time |

1. Outdoor construction

possible 2. Excellent in hardness and elasticity 3. Anti-noise, anti-dust effects 4. Displays clear colors 5. Vulnerable to contamination 6. Defects occur in large numbers at a later time (swollenness or delamination) 7. Over-production of industrial waste during reconstruction |

1. Thick-coating type of

chemical resistance 2. Easy to apply 3. Displays clear colors 4. Vulnerable to contamination 5. Defects occur in large numbers at a later time (swollenness and delamination) 6. Over-production of industrial waste during reconstruction |

1. Easy to apply 2. Low construction cost 3. The likes of swollenness frequently take place , resulting in reconstruction on a regular basis. 4. A very large number of defects occur at a later time. 5. Over-production of industrial waste during reconstruction |

| Product lifespan | Semi-permanent, long-term use | Regular maintenance and reconstruction required (approx. every three years) | Regular maintenance and reconstruction required (approx. every three years) | Regular maintenance and reconstruction required (approx. on a yearly basis) |

| Product name | WINGSCHEM |

|---|---|

| Model name | NSD-1110 (Oil-based) |

| Color | Manufacturing customized for orders |

| Purpose and usage | Concrete polishing (for use indoors and outdoors - strong UV resistance) |

| Materials | Organic compounds, organic and inorganic coloring dyes, etc. |

| Volume | 18kg |

| Country of manufacture | Korea |

| Manufacturer /Sales agent |

Woori Industrial Development Co., Ltd |

| Product name | WINGSCHEM |

|---|---|

| Model name | NAD-1110 (Water-based) |

| Color | Manufacturing customized for orders |

| Purpose and usage | Concrete polishing (for use indoors) |

| Materials | water, organic compounds, coloring dyes, etc. |

| Volume | 18kg |

| Country of manufacture | Korea |

| Manufacturer /Sales agent |

Woori Industrial Development Co., Ltd |